Aerospace Industry

Enhance Aerospace Assembly with Innovative Solutions

Aerospace Industry

Welcome to Conveyability’s comprehensive guide to conveyors in the Aerospace Industry. As a leading provider of innovative material handling solutions, we take pride in offering cutting-edge conveyor systems that optimize aerospace manufacturing and assembly processes, ensuring smooth operations, precise handling, and maximum efficiency.

The Role of Conveyors in Aerospace Manufacturing

In the dynamic and complex aerospace industry, precision, reliability, and safety are paramount. Conveyors play a crucial role in streamlining various stages of aircraft assembly and component manufacturing, delivering a range of benefits that help aerospace companies stay competitive and achieve excellence.

Benefits of Conveyors in the Aerospace Sector

Assembly Line Efficiency: Aerospace assembly requires seamless coordination of components and precise sequencing. Conveyors facilitate the movement of fuselage sections, wings, engines, and other aircraft parts through the assembly line, ensuring a smooth and efficient workflow.

Safe Handling of Fragile Components: The aerospace industry deals with delicate and expensive components. Conveyor systems equipped with features like cushioned belts, adjustable speeds, and specialized fixtures ensure gentle product handling, reducing the risk of damage.

Ergonomic Solutions: Manual material handling can be physically demanding for workers. Conveyors minimize the need for lifting and carrying heavy parts, contributing to a safer and more ergonomic work environment.

Modularity and Flexibility: Conveyability’s conveyor solutions are designed with modularity in mind, allowing aerospace manufacturers to easily adapt and reconfigure their production lines as project requirements change.

Quality Control and Traceability: Conveyor systems integrated with advanced tracking and identification technologies enable seamless quality control and component traceability throughout the assembly process, ensuring compliance with stringent industry standards.

Lean Manufacturing Principles: Conveyors help implement lean manufacturing principles by eliminating unnecessary movements and reducing non-value-added activities, leading to increased productivity and reduced production lead times.

Space Optimization: Aerospace facilities often have limited space, and conveyor systems enable vertical integration, optimizing floor space and maximizing the use of available square footage.

Applications of Conveyors in the Aerospace Sector

Aircraft Component Manufacturing: Conveyors are used to transport various aircraft components, such as wings, fuselage sections, and tail assemblies, between workstations, ensuring efficient production and timely delivery.

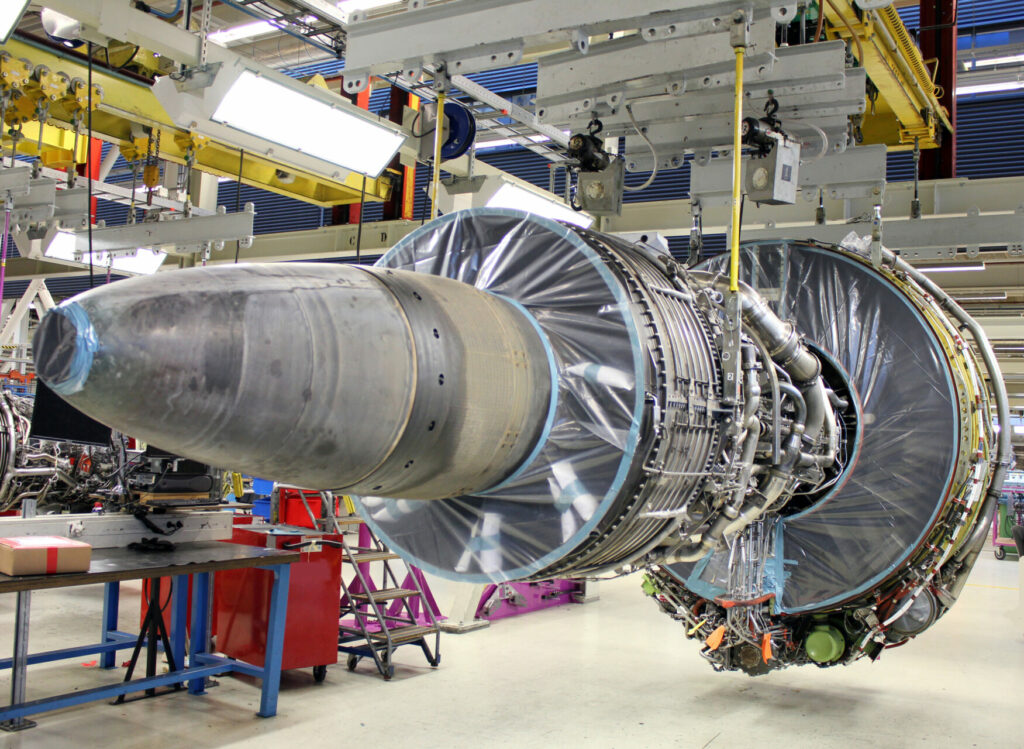

Engine Assembly: Conveyor systems facilitate the assembly of complex aircraft engines by seamlessly transporting engine components through different stages of the manufacturing process.

Cabin Interior Installation: Conveyors aid in the installation of cabin interiors, such as seats, overhead bins, and galleys, ensuring precise positioning and timely cabin completion.

Testing and Inspection: Conveyor systems are utilized in aerospace testing and inspection processes, allowing components and systems to be smoothly moved through inspection stations for thorough evaluation.

Final Assembly and Aircraft Integration: Conveyors play a crucial role in the final assembly of aircraft, supporting the movement of fully assembled sections to be integrated into a complete aircraft.

At Conveyability, we specialize in designing and implementing customized conveyor solutions tailored to the unique needs of the aerospace industry. Our team of experts is committed to providing you with reliable, high-performance conveyor systems that enhance your aerospace manufacturing process, improve operational efficiency, and drive success. Contact us today to learn how our conveyors can help your aerospace business soar to new heights!